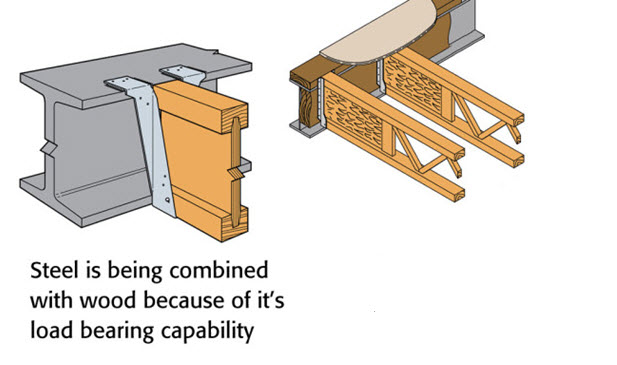

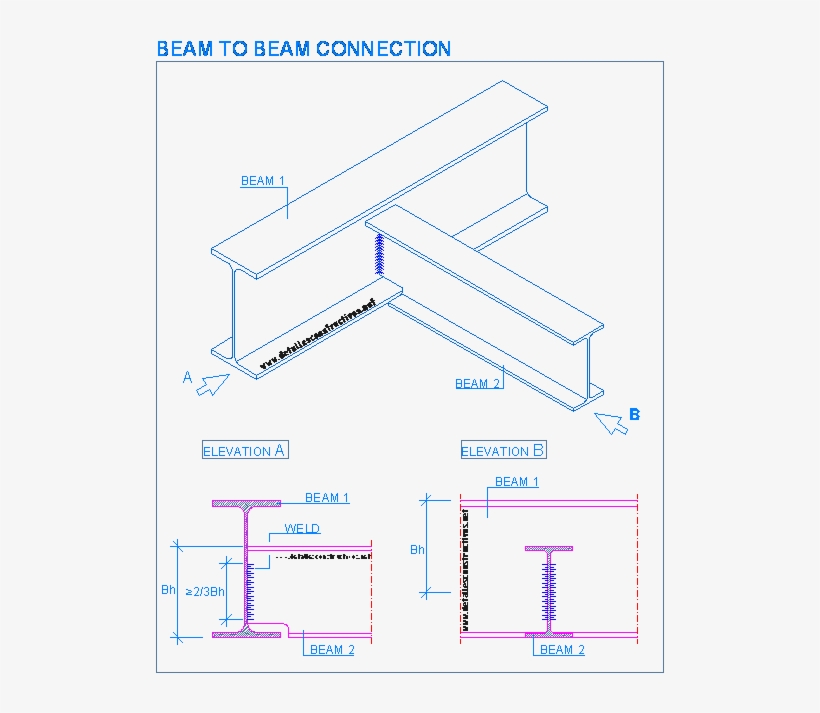

Connectors can also be ordered in a variety of custom sizes for post and beam framing, including angles Call to discuss your project;63 Structural Steel Connections, Joints and Details Objective and Scope Met • Modldule 1 Welds – Introduction – Basics of welding – Fillet weld – LRFD of welded connections – Eccentric shear in welds BMA Engineering, Inc – 6000 29 63 Structural Steel Connections, Joints and Details –There are various types of steel beam connections used in structures Steel beam connections are categorized into two groups namely framed and seated connections In the framed steel beam connections, the beam is connected to the supporting steel element through fittings whereas in case of seated connections, the beam is positioned on seat similar to the case where beam is placed on masonry walls

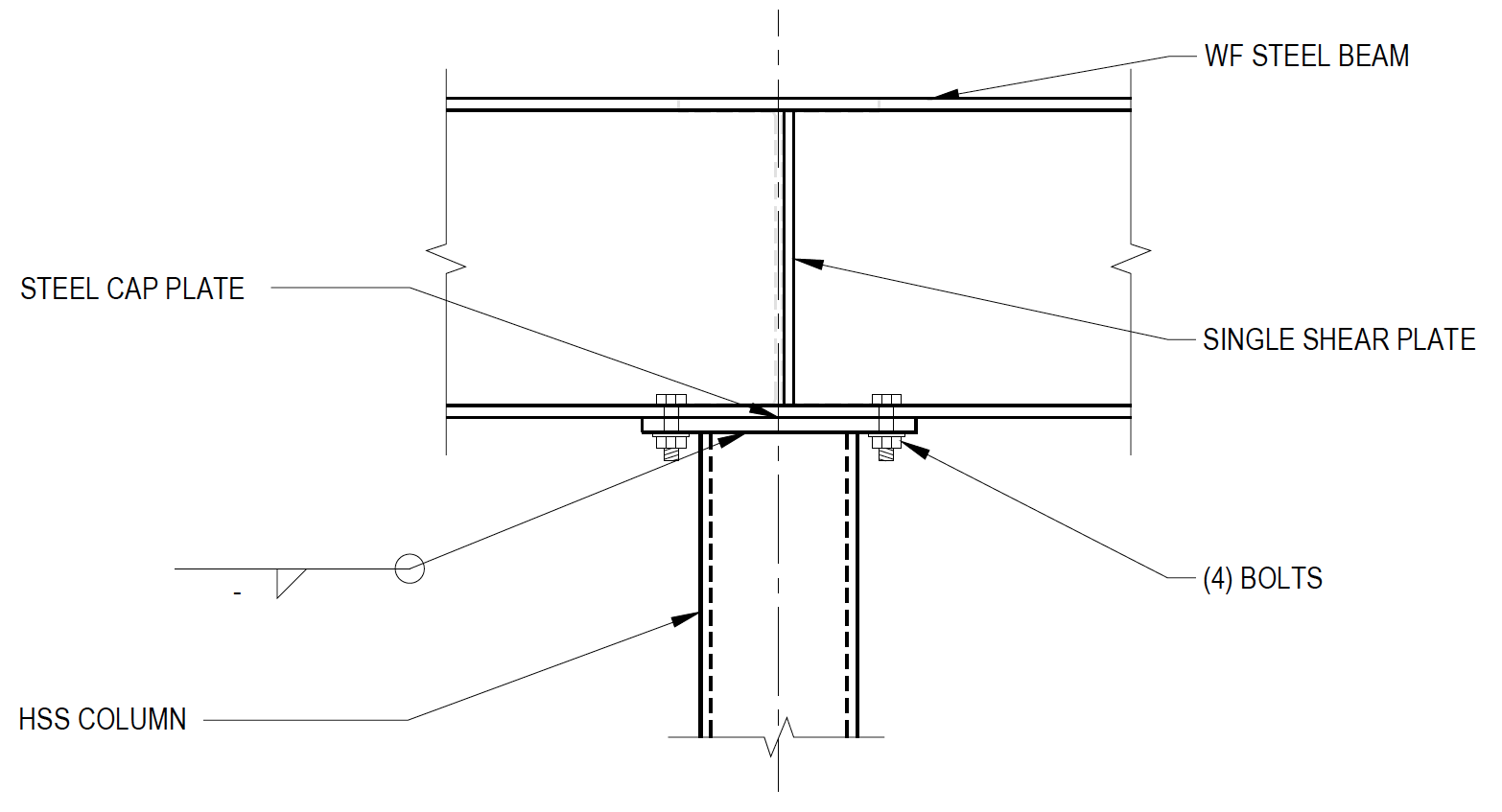

Beam Shear Connection

I beam connection to concrete column

I beam connection to concrete column-Qualward IBeam Heavy Bag Hanger, Heavy Duty Steel 315" W Beam Clamp Hook, Punching Bag Hanger for Boxing, Muay Thai & MMA Training 45 out of 5 stars 223 $4299 $ 42 99 $5699 $5699 Get it as soon as Fri, Feb 26 FREE Shipping by AmazonSteel and beam anchors attach to structural steel (such as an Ibeam, Hbeam, or pipe) to serve as a tieoff point for a fall arrest device They are clamped, welded, or bolted in place They often have a smaller footprint than other connectors and can be used where the mounting point is not fully exposed, such as anchors that clamp onto beams

Offset I Beam Connection And Support Simplified Building

2 Presented by Jared S Hensley, PE Connection Design Solutions For Wood Frame Structures Disclaimer This presentation was developed by a third party and isConcealed connection systems rely on embedding the connectors, whether wood tenons or metal plates, within the thickness of the posts or beams While mortise and tenon joints were originally fashioned onsite in traditional post and beam construction, stock connectors are now availableIBeam Connector Clamp Applications Beam Clamps give the ability to adjust distance between the legs of the Gantry Crane without drilling more holes This The effective IBeam length (distance between the crane legs) is a big part of crane capacity, so shortening the For special cases, and

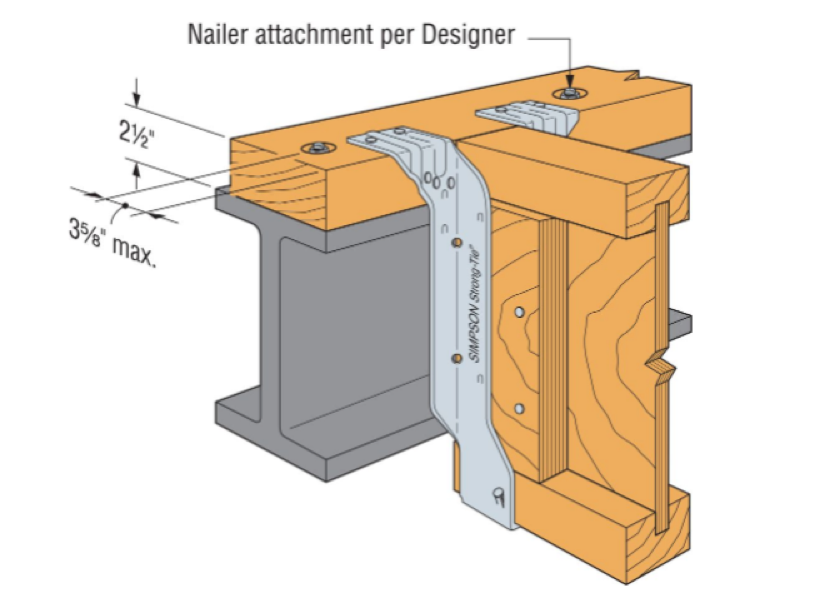

All orders are taken personally over the phone STANDARD CONNECTORS There are (21) standard connector sizes always available for any type of post and beam building projectThe most common method for attaching perpendicular joists to a steel Ibeam situated within a floor system involves the use of joist hangers There are a couple installation options Frequently, the top of the Ibeam is capped with a wood plate to which topmount joist hangers can be nailedThe IBeam Connector Clamp can be used to attach other items to the beam in a nonpermanent way, and without drilling holes into the Ibeam The extra item need only have a flat plate to match the beam Mount the IBeam Connector Clamp anywhere along the beam, then it will act as a very effective trolley stop

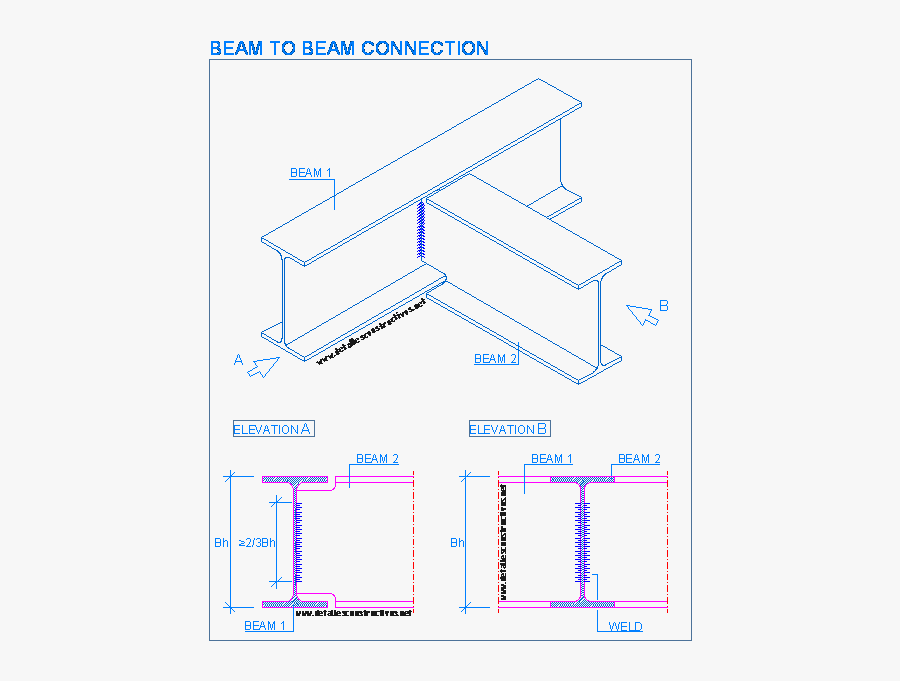

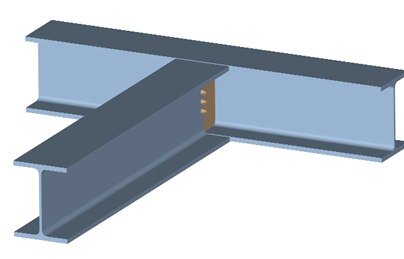

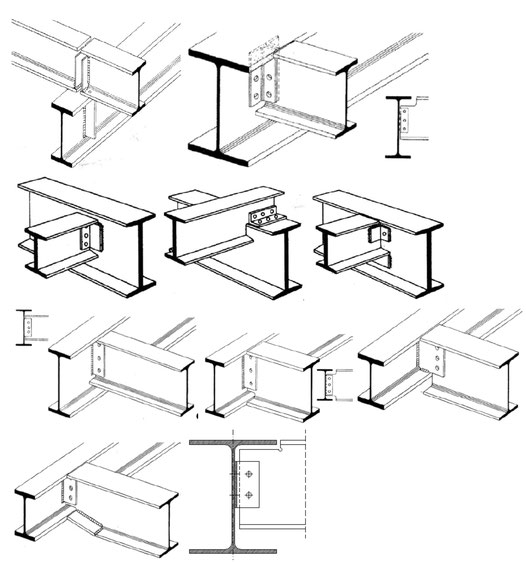

Clip angle beam/beam web Using the clip angle beam/beam web steel connection type, you can connect a secondary beam to the web of the main beam with either a bolted or a welded connection The welded connection can be to the secondary beam, to the main beam, or to both Metal Beam Steel Beams Metal CeilingQualward IBeam Heavy Bag Hanger, Heavy Duty Steel 315" W Beam Clamp Hook, Punching Bag Hanger for Boxing, Muay Thai & MMA Training 45 out of 5 stars 223 $4299 $ 42 99 $5699 $5699 Get it as soon as Fri, Feb 26 FREE Shipping by Amazon2 Presented by Jared S Hensley, PE Connection Design Solutions For Wood Frame Structures Disclaimer This presentation was developed by a third party and is

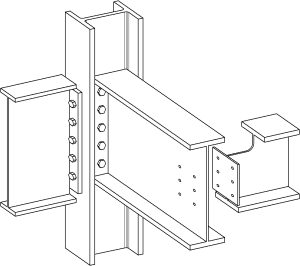

Column Connection An Overview Sciencedirect Topics

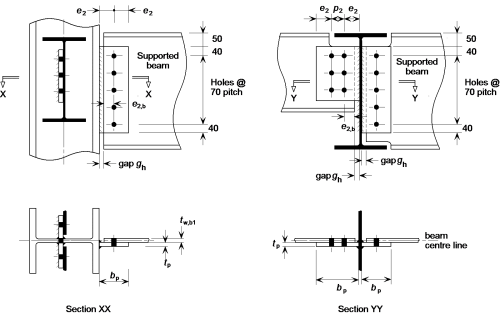

Simple Connections Steelconstruction Info

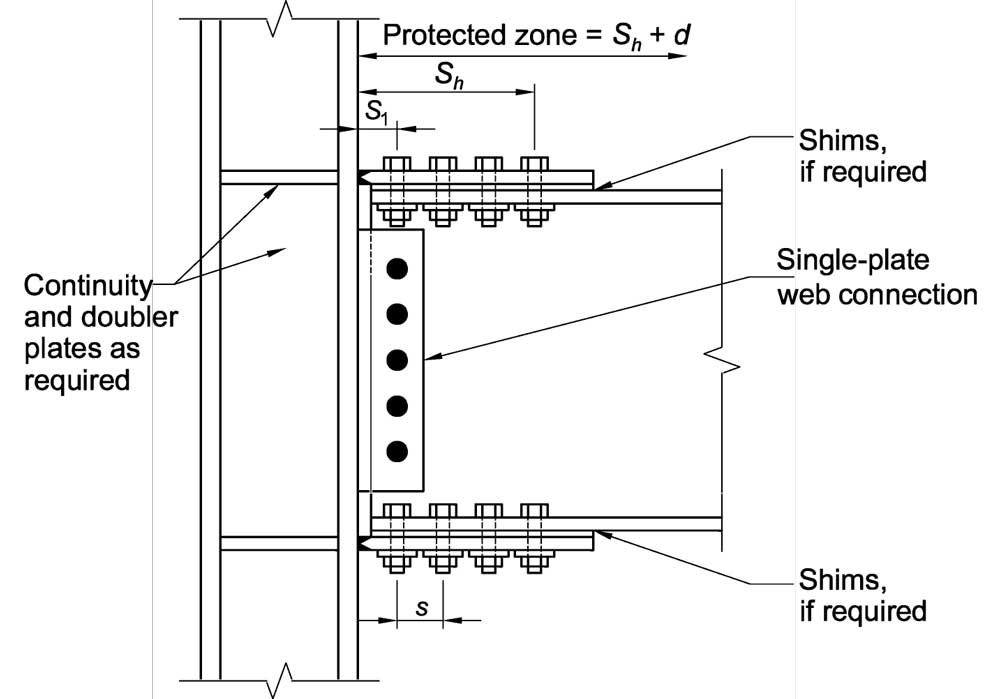

Simpson StrongTie category "Wood Construction Connectors" We use cookies on this site to enhance your user experience By clicking "I AGREE" below, you are giving your consent for us to set cookiesA moment connection connects the beam/col flanges In the 2column direction, the "flanges" of your pipe are connected to the beam, so this is a moment connection within a moment frame A shear connection is only to the beam web, which acts like a hinge This is the case for your minor beam ends in the 3column directionPretensioned bolts have applications in the following connections (i) Column splices in multistoreyed structures over 40 m in height (ii) Connection of beams and girders to columns or to beams and girders on which the bracing of columns is dependent, in structures over 40 m in height

Connection Of I Beam To Box Column By A Short Stub Beam Sciencedirect

Splice Connections Of I Beam Flanges Idea Statica

One way to attach joists to a recessed steel Ibeam is to install the perpendicular joist so that the bottom chord bears on the bottom beam flange (inside the "I") This most often involves trimming the joist end with an angled "bevel cut" or "fire cut" so that the top flange of the Ibeam doesn't get in the way of the joist's top chordHeavy Timber construction uses beams and stringers that are connected with bolts and gusset plates or traditional wood joinery with pegs and dovetails The element that most defines a timber framer is the quality, integrity and strength of the joints that hold the beams together A properly made joint will stay tight for generationsIn this article you find the seven most used beam connections, prepared for welding and/or fastening But it also provides a clear insight into unlimited possibilities for H beam coping Example 1 Left a bolted beam to beam connection, sloped shear tab connection with notches and an intermediate

What Are The Available Calculated Steel Connections From Advance Design Steel Connections Graitec

Connection Of I Beam To Box Column By A Short Stub Beam Sciencedirect

Also known as American Standard I Beams, these Ibeams have rounded corners Architectural 6063 Aluminum HBars More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is primarily used for exterior railings, decorative trim, and door framesConnections (in beam to column connections in frames) Ideal concentric connections should have only one bolt passing through all the members meeting at a joint Fig 1(a) However, in practice, this is not usually possible and so it is only ensured that the centroidal axes of the members meet at one point See Fig 1(b)These Scat Ibeam connecting rods incorporate all of the best features possible for an Ibeam rod, including some strength adders found in Hbeam designs Scat Pro Comp Ibeam connecting rods are profiled with clearance for long stroke applications

Offset I Beam Connection And Support Simplified Building

Types Of Steel Beam Connections And Their Details

The Shape and Structure of the IBeam The I beam consists of two horizontal planes, known as flanges, connected by one vertical component, or the web The shape of the flanges and the web create an "I" or an "H" crosssection Most I beams use structural steel, but some are made from aluminumStronger post to beam connections jlc connectors connext post and beam steel column and brackets a bracing a house with steel thrulok through bolt replacement multi Structure Steel To WoodAlso known as American Standard IBeams, these Ibeams have rounded corners Architectural 6063 Aluminum HBars More corrosion resistant and easier to form than multipurpose 6061 aluminum, 6063 is primarily used for exterior railings, decorative trim, and door frames

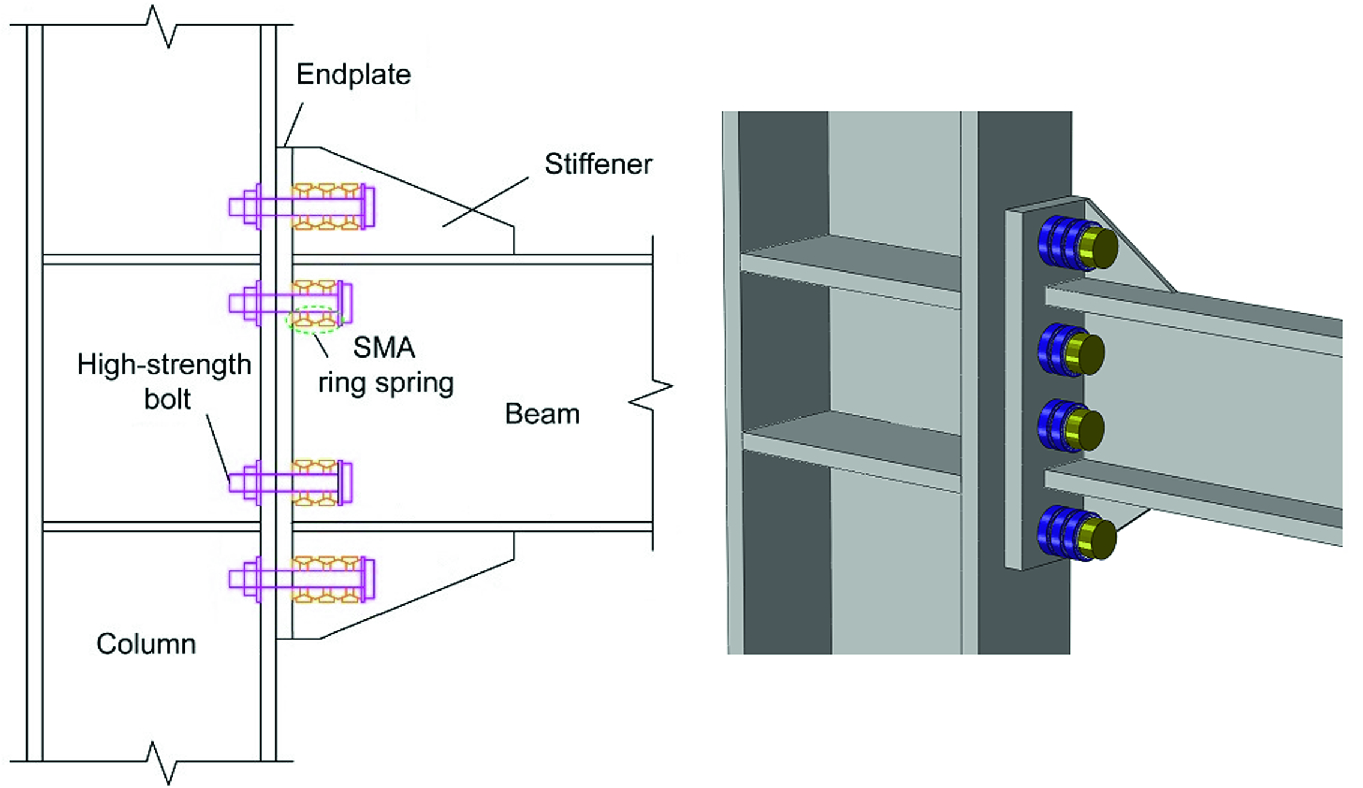

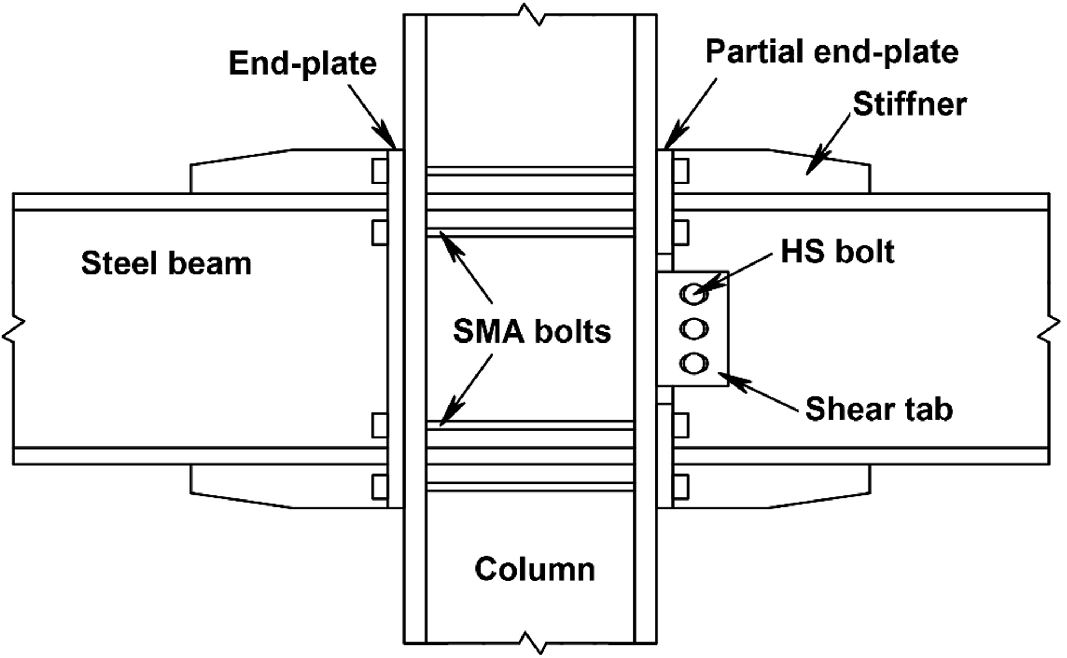

Steel Beam To Column Connections With Sma Elements Springerlink

Steel Beam Reinforced Concrete Wall Endplate Moment Connection

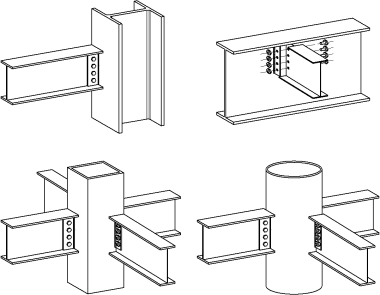

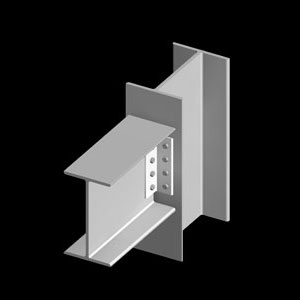

6x6 Post Cap Connectors Post Caps Simpson StrongTie ECCLL LShape End Column Cap for 6x Post, 6x Beams, Skewed Left (4) Model# ECCLL666 $ 8 23 Simpson StrongTie ECC End Column Cap 6x Beam, 6x Post (9) Model# ECC66 $ 76 34Connectors can also be ordered in a variety of custom sizes for post and beam framing, including angles Call to discuss your project;Steel Connections Dr Seshu Adluri Beam to Column Rigid Joints Stiffener plates are used to 'shore up' the column flanges against the forces transmitted by the beam flanges The stiffeners may be full length or may extend only part of the column web depth

Connections For Simple Beams Civil Engineering

Moment Resisting Connections Steelconstruction Info

BEAM TO BEAM CONNECTION STUDY MODEL MAKING By using plywood making a model of BEAM TO BEAM CONNECTION PLEASE Like 👍🏻, Share , Comment 🖋️ and SubscrGenerally it should be at least 3 inches into the concrete If you want you can install 2 anchor bolts at the bottom of the beam pocket which will secure a piece of 2x pressure treated for the beam to sit on Detail 5 is the other option which calls for a column adjacent to the concrete wall to carry the beamBrand Burndy 28 Show More Show Less Product Family Grounding and Bonding Connectors>"Hyground" Compression Grounding Connectors>Cable to Steel/Bar 28

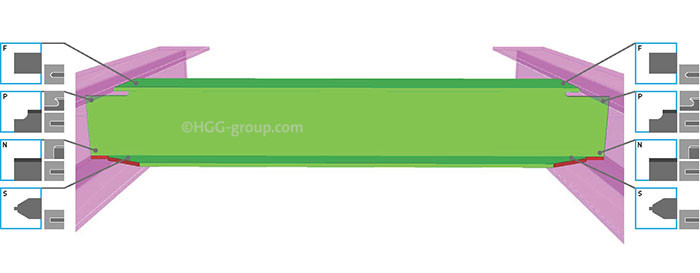

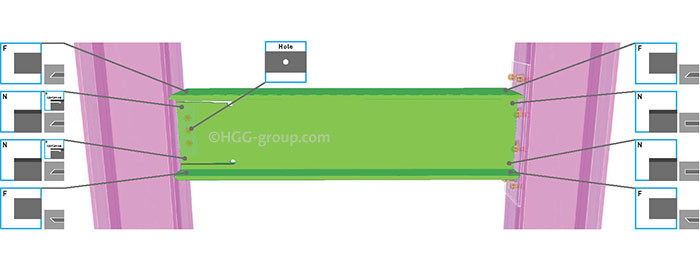

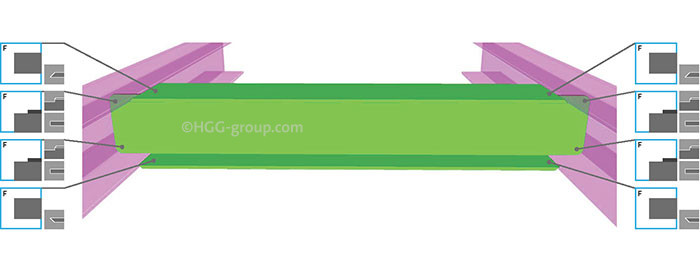

The 7 Most Used Beam Connections Explained Hgg 3d Profiling

Steel Connections For Beams And Columns Skyciv Cloud Structural Analysis Software

BEAM TO BEAM CONNECTION STUDY MODEL MAKING By using plywood making a model of BEAM TO BEAM CONNECTION PLEASE Like 👍🏻, Share , Comment 🖋️ and SubscrBeams are connected to main beams or into the columns The design of these connections is more important since the failure of connection is more catastrophic than the failure of the beam section In this chapter different types of a beam, connections are explained As discussed in IS recognizes the following three types of steel framework construction, depending upon the typeIn most cases the beams you're designing are intended to carry vertical loads only For that reason most building officials and engineers are not very critical with the connection design of beam to column connections With regard to your question, there are two connection options that I can think of Detail b4 above provide one of the options

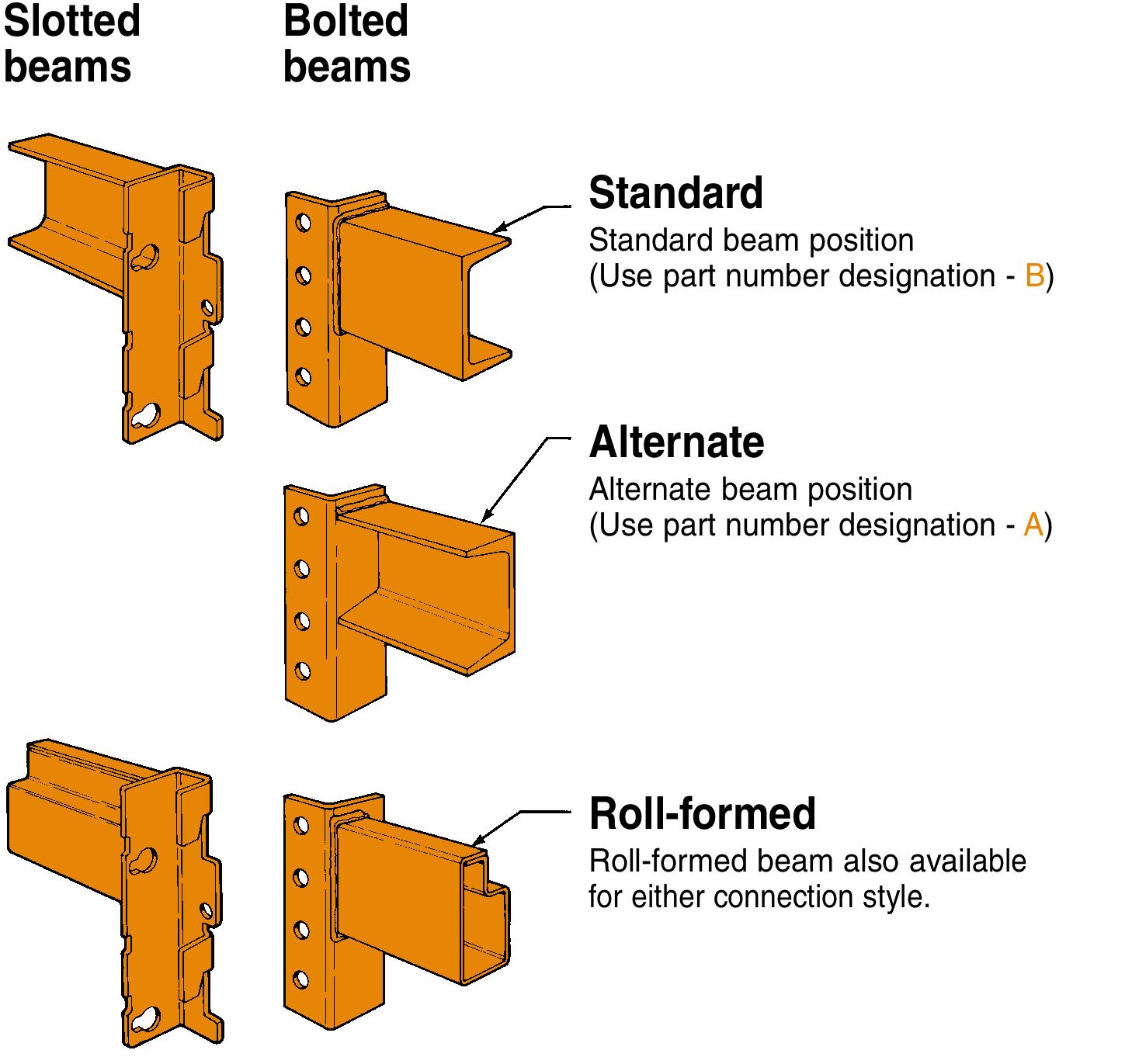

Beam Connections Ridg U Rak

How Are Connections Between Block Columns And H Beams Done Quora

Steel beam connections without hangers Here's another type of attachment, using a steel beam with wood filler fixed only to the top and bottom flanges It doesn't need a bottom flangebearing hanger as you can cut away the trimmable end of the open joist TRIFORCE ® at an angle, to achieve the supportThe connection between the steel beams (designed by the valid standards MKS UE7140 correlated with EC3) was realized by the modified beamcolumn connection using endplate connection that was welded to beam Here, same as the previous model, endthe end of the beam At the end plate 2 holes were made (d=17mm), deployed in 4 rows,The most underappreciated connection on a deck frame is probably the one between a post and the beam it supports Although this joint may not get the respect it deserves, it is a critical loadpath connection that needs to keep the post and beam aligned while properly transferring deck loads to the footing

The 7 Most Used Beam Connections Explained Hgg 3d Profiling

Structural Connections In Revit 17 Autodesk Community Revit Products

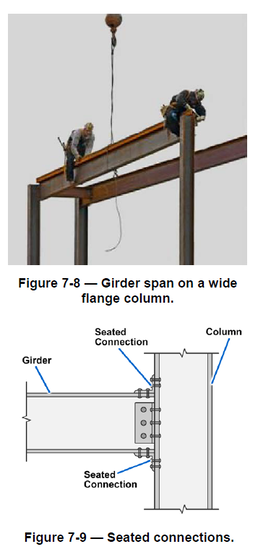

Types of Beam Connections In general, all beam connections are classified as either framed or seated In the framed type, the beam is connected to the supporting member with fittings (short angles are common) attached to the beam web With seated connections, the ends of the beam rest on a ledge or seat, in much the same manner as if the beam rested on a wallJan 17, 17 Explore John Jeffrey Rigor's board "IBEAM CONNECTION" on See more ideas about steel columns, steel structure, steel designJoin two beams in a straight line without drilling or welding The bolt can be removed to insert threaded rod Zincplated iron clamps have mild corrosion resistance Galvanized iron clamps have better corrosion resistance than zincplated iron clamps

Www Google Com Blank Html Steel Columns Steel Structure Buildings Steel Structure

9 Metal Beam Connections Ideas Metal Beam Beams I Beam

Bolts were utilized for glulam beamtobeam connections This chart shows 10 nails, all referred to as 10d, and each with potentially different performance characteristics Thus, specifying a 10d nail is not clear Photos Josh Partee Photography 10d NailsConnections with field welded beam flanges and field bolted flange plates MOMENT CONNECTION WITH FIELD WELDED BEAM FLANGES (FIGURE 1) 1 The connection plates must be the same grade of material as the weak axis moment beam 2 The connection plate has been extended ¾" minimum beyond the column flange to provide better toughness and ductilityFastFit is a preengineered "all purpose" Ibeam connection solution that can be used to connect many different beams of varying sizes and angles If playback doesn't begin shortly, try restarting your device Videos you watch may be added to the TV's watch history and influence TV recommendations

Types Of Steel Beam Connections And Their Details

Wood To Steel Connections Making Sure It S Done Right Triforce Open Joist

In general, all beam connections are classified as either framed or seated In the framed type, the beam is connected to the supporting member with fittings (short angles are common) attached to the beam web With seated connections, the ends of the beam rest on a ledge or seat, in much the same manner as if the beam rested on a wallUsing the clip angle beam/beam web steel connection type, you can connect a secondary beam to the web of the main beam with either a bolted or a welded connection The welded connection can be to the secondary beam, to the main beam, or to bothBeam connections of the types shown in Figure 111 (p 398 of the textbook) • The designer can select most of these connections by simply referring to these standard design tables To qualify as a simple end connection, the end of the beam should be as free as

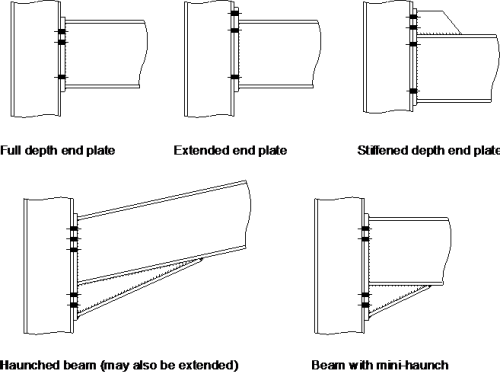

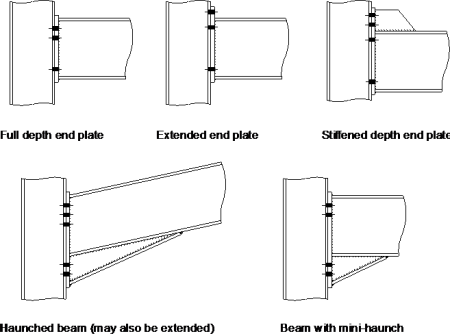

What Is End Plate Connection Design For Metal Beam Structures

The 7 Most Used Beam Connections Explained Hgg 3d Profiling

Single sided beamtocolumn joint configuration, bolted endplate connection M V 15 3 IPE2 HEB140 1 60 10 30 80 30 240 4 M16 140 p=60 u=10 5 w= To be evaluated Design moment resistance , initial stiffness 0 1 1,0 1,0 M M J J Material S 235Jan 17, 17 Explore John Jeffrey Rigor's board "IBEAM CONNECTION" on See more ideas about steel columns, steel structure, steel designAll orders are taken personally over the phone STANDARD CONNECTORS There are (21) standard connector sizes always available for any type of post and beam building project

Simple Connections Steelconstruction Info

Steel Connections For Beams And Columns Skyciv Cloud Structural Analysis Software

It is a cast steel connector that acts as a node to resolvea number of tensile forces Upon closer examination one can notice thatthe connection is made of a number of parts Each cable is connected tothe node by an end "bracket" which is connected to a large pin This is quite literally a "pinned connection"Product Description Fast Fit is an off the shelf engineered Ibeam clamping solution to connect two steel Ibeams together without the need for onsite drilling or welding All you need to secure two sections together comes in one box The system comprises a frame which wraps around the edges of the sections and slides into place to provide a position for the clamps to be securedThe Shape and Structure of the IBeam The I beam consists of two horizontal planes, known as flanges, connected by one vertical component, or the web The shape of the flanges and the web create an "I" or an "H" crosssection Most I beams use structural steel, but some are made from aluminum

Steel Beam To Column Connections With Sma Elements Springerlink

I Beam T Joint I Beam Beams Steel Conection

14 A Un Stiffened And B Stiffened End Plate Beam To Column Download Scientific Diagram

Introduction Beam To Column Connection

Construction Beam To Beam Connection Youtube

Beam To Hss Column Connection Structural Engineering General Discussion Eng Tips

What Are The Available Calculated Steel Connections From Advance Design Steel Connections Graitec

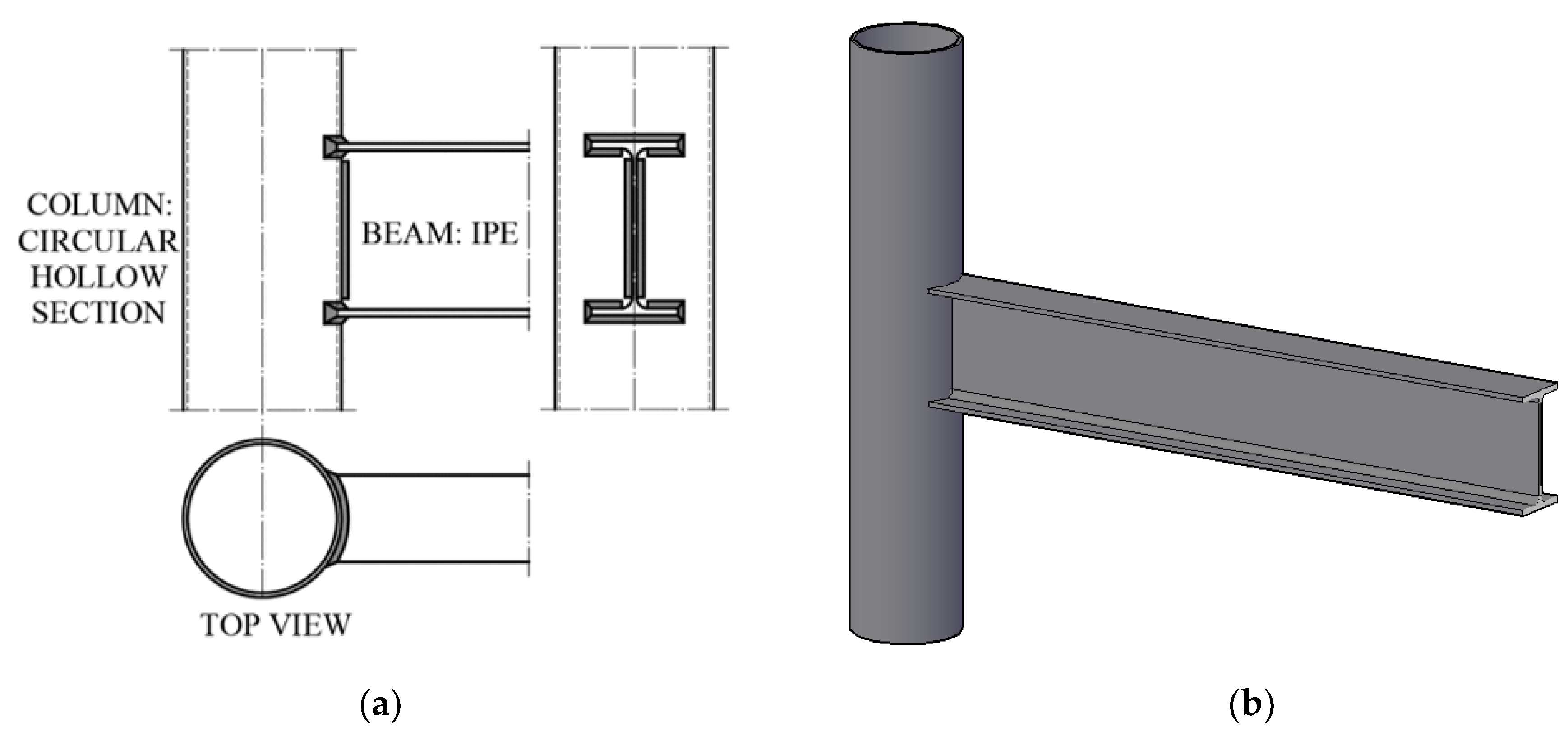

The Static Strenght Of I Beam To Circular Hollow Section Column Connections Semantic Scholar

Seismic Performance Of Steel Beam To Column Moment Connections With Different Structural Forms Sciencedirect

I Beam On T Beam Connection Autodesk Community Robot Structural Analysis Products

Structural Steel Drawings Computer Aided Drafting Design

Materials Free Full Text Stiffness Prediction Of Connections Between Chs Tubes And Externally Welded I Beams Fe Analyses And Analytical Study Html

I Beam Vs Square Tube For Columns Structural Engineering General Discussion Eng Tips

What Are The Available Calculated Steel Connections From Advance Design Steel Connections Graitec

1 Types Of Beam To Column Connections Download Scientific Diagram

Detail Of Beam Connection Simple Framing Connection Semi Rigid Framing Connection Rigid Frame Connection

9 Metal Beam Connections Ideas Metal Beam Beams I Beam

Moment Resisting Connections Steelconstruction Info

Offset I Beam Connection And Support Simplified Building

Offset I Beam Connection And Support Simplified Building

Behavior Of I Beam Bolted Extended End Plate Moment Connections Sciencedirect

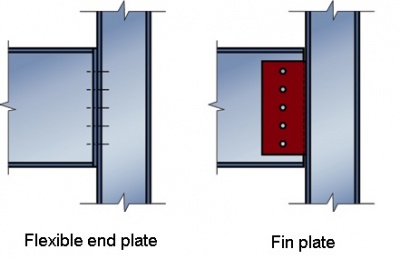

Beam To Column Connection With End Plate Engineering Manuals Fin Ec Online Help

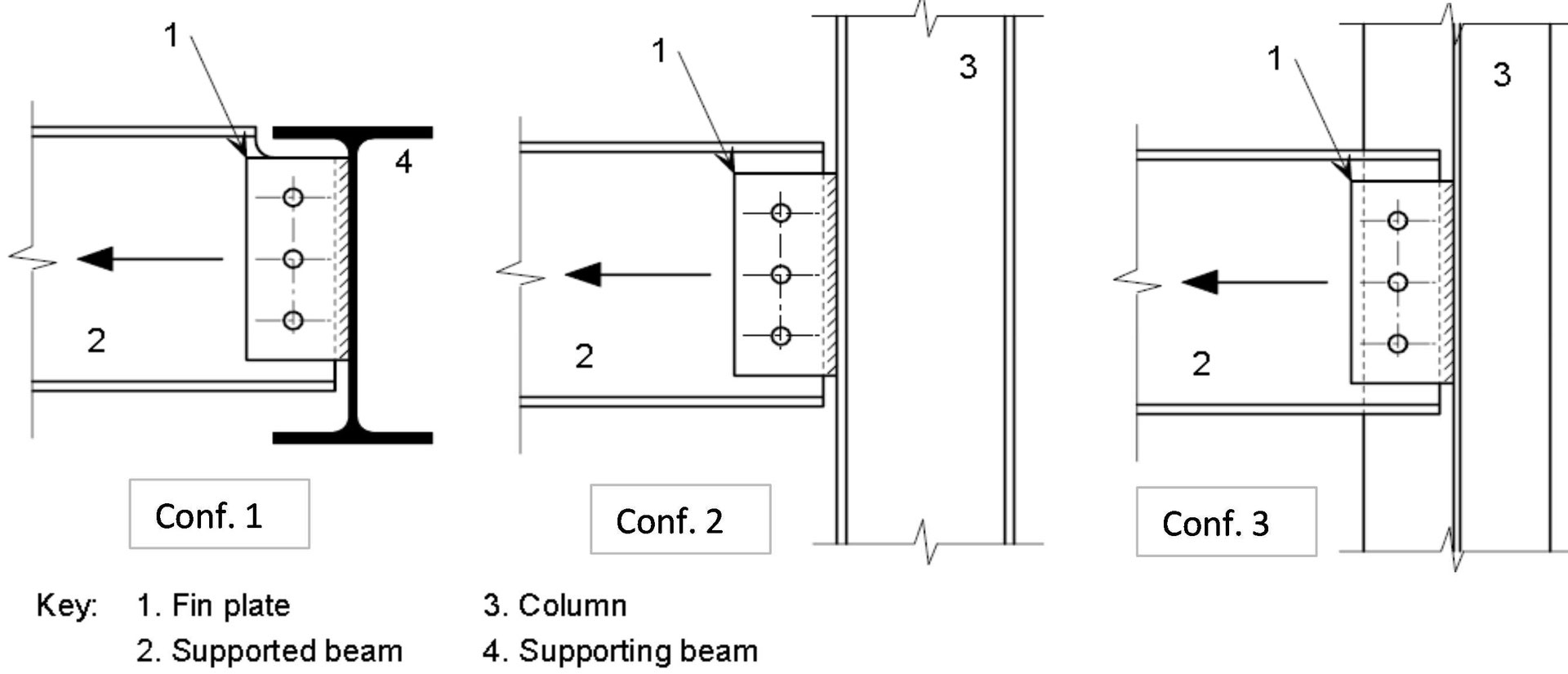

Fin Plate Connection Mec Engineering Spreadsheets

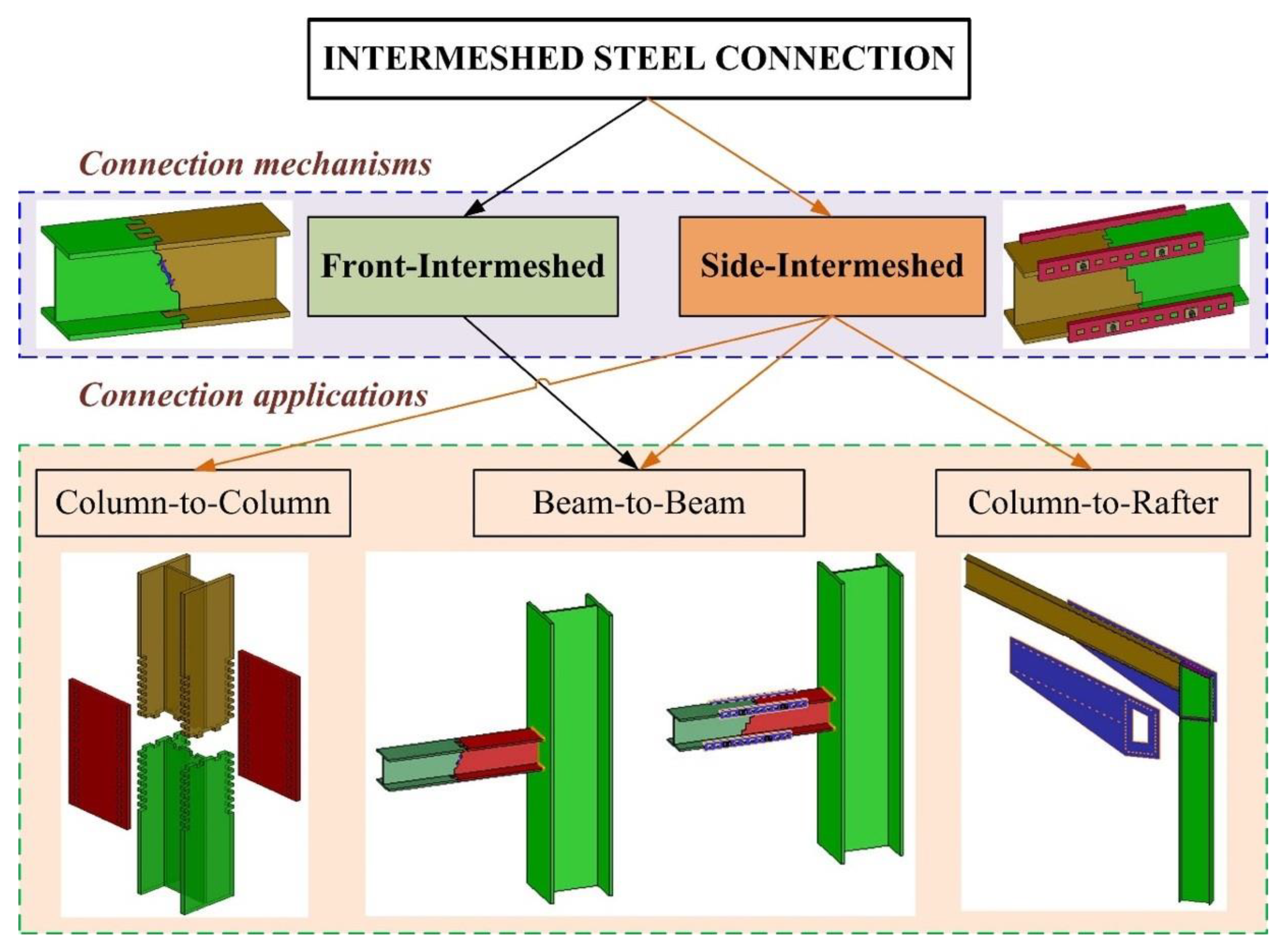

Buildings Free Full Text Introduction Of The Intermeshed Steel Connection A New Universal Steel Connection Html

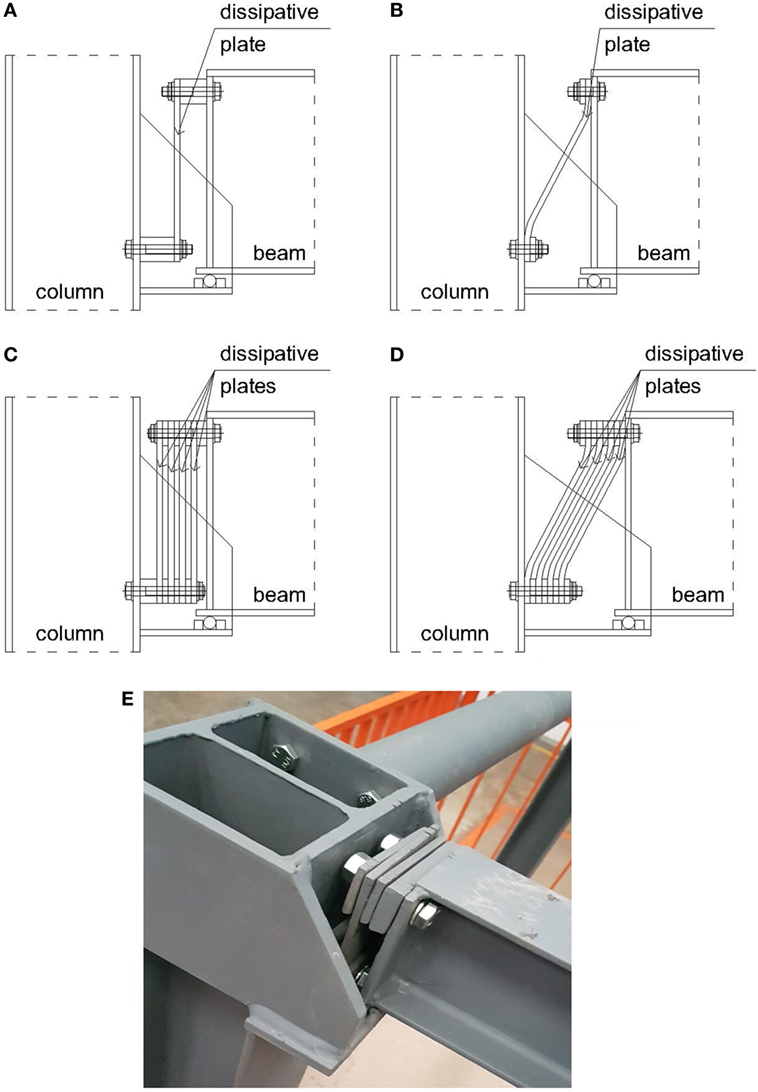

Frontiers Beam To Column Connections With Demountable Energy Dissipative Plates Built Environment

Solved How To Design Concrete Column Steel Beam Connection Autodesk Community Robot Structural Analysis Products

Structural Steel Drawings Computer Aided Drafting Design

Simple Connections Steelconstruction Info

Bolt And Nut With Vertical Axis Connecting Beam To Column Welding Bonding Fastener Engineering Eng Tips

Externally Reinforced Welded I Beam To Box Column Seismic Connection Journal Of Engineering Mechanics Vol 136 No 1

Simple Connections Steelconstruction Info

Wood To Steel Connections Making Sure It S Done Right Triforce Open Joist

Steel Connections Beam To Beam Welded Connection Free Transparent Clipart Clipartkey

Steel Structures And Connections In Revit Tutorial Youtube

Types Of Steel Beam Connections And Their Details Beam Structure Welding

Steel Beam Connections Construction Cost

Beam Shear Connection

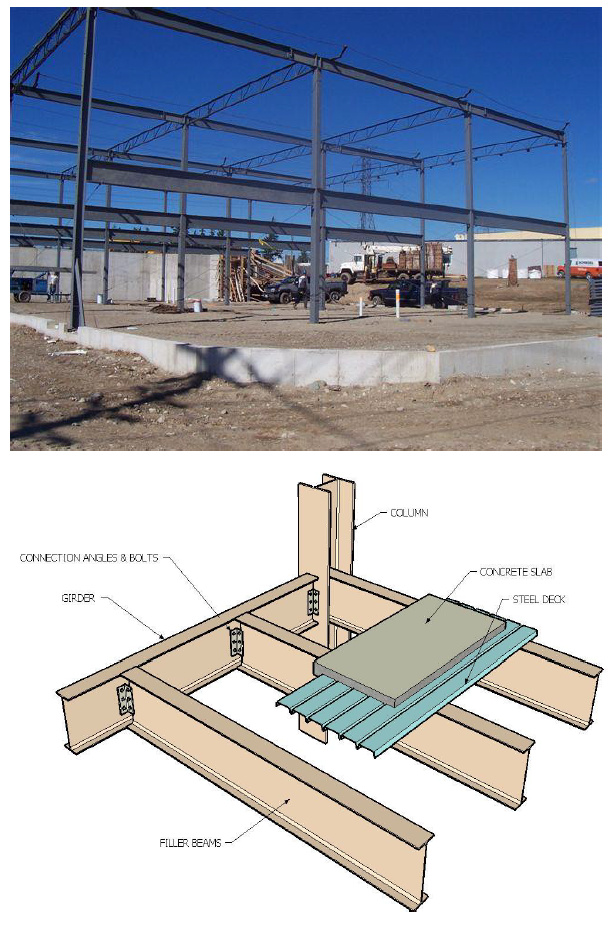

Ssef Fun Is In The Details Understanding Framing

Steel Beam Connections Beam To Beam Connection Steel Free Transparent Png Download Pngkey

Refined Analysis Of Fatigue Crack Initiation Life Of Beam To Column Welded Connections Of Steel Frame Under Strong Earthquake

The Static Strenght Of I Beam To Circular Hollow Section Column Connections Semantic Scholar

Steel Connections Designer Clip Angle Graitec

Connection Of I Beam To Box Column By A Short Stub Beam Sciencedirect

What Is Difference Between Moment Connection And Shear Connection In Steel Structures Quora

Beam Connection 3d Warehouse

Steel Framework Joints Mec Engineering Spreadsheets

Column Beam Connections 3d Warehouse

Ssef Fun Is In The Details Understanding Framing

Structure Magazine Unanticipated Stresses And The Welded Flange Plate Moment Connection

Structure Steel To Wood Home Building In Vancouver

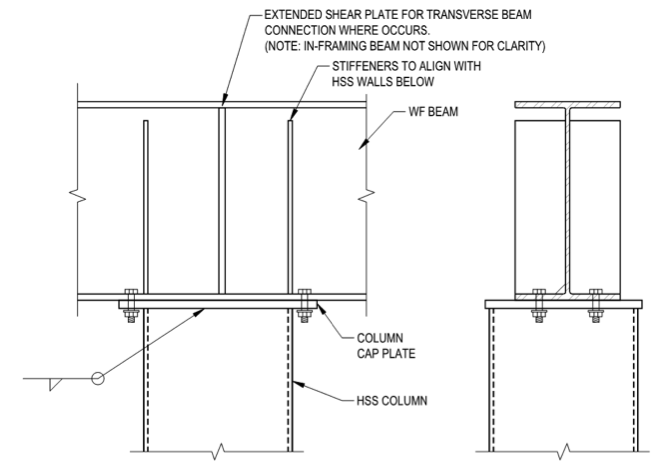

Hss Limit States In Cap Plate Connections Steel Tube Institute

Monotonic Loading Tests Of Ring Beam Connections For Steel Reinforced Concrete Columns And Rc Beams Journal Of Structural Engineering Vol 140 No 4

Steel Connections Software Cse Tour Beam To Beam Welded Joint Youtube

Beam To Beam Moment Connection Structural Engineering General Discussion Eng Tips

Steel Connections For Beams And Columns Skyciv Cloud Structural Analysis Software

Types Of Steel Beam Connections And Their Details

Wide Flange Beam To Hss Column Moment Connections Steel Tube Institute

Ssef Fun Is In The Details Understanding Framing

Types Of Steel Beam Connections And Their Details

Types Of Joints Beam To Column Connection

Types Of Steel Connections And Their Classifications Skyciv Cloud Structural Analysis Software

Cfs A Apex And B Eaves Connections With Back To Back Beam Sections Download Scientific Diagram

Types Of Steel Beam Connections And Their Details

Solved Structural Connections Welded Connection Of Two Beams Autodesk Community Revit Products

Offset I Beam Connection And Support Simplified Building

9 Metal Beam Connections Ideas Metal Beam Beams I Beam

Pin By Xintong Zhao On Architecture Steel Trusses Steel Architecture Steel Structure

Connections Of Steel Beams Dwg Detail For Autocad Designs Cad

No comments:

Post a Comment